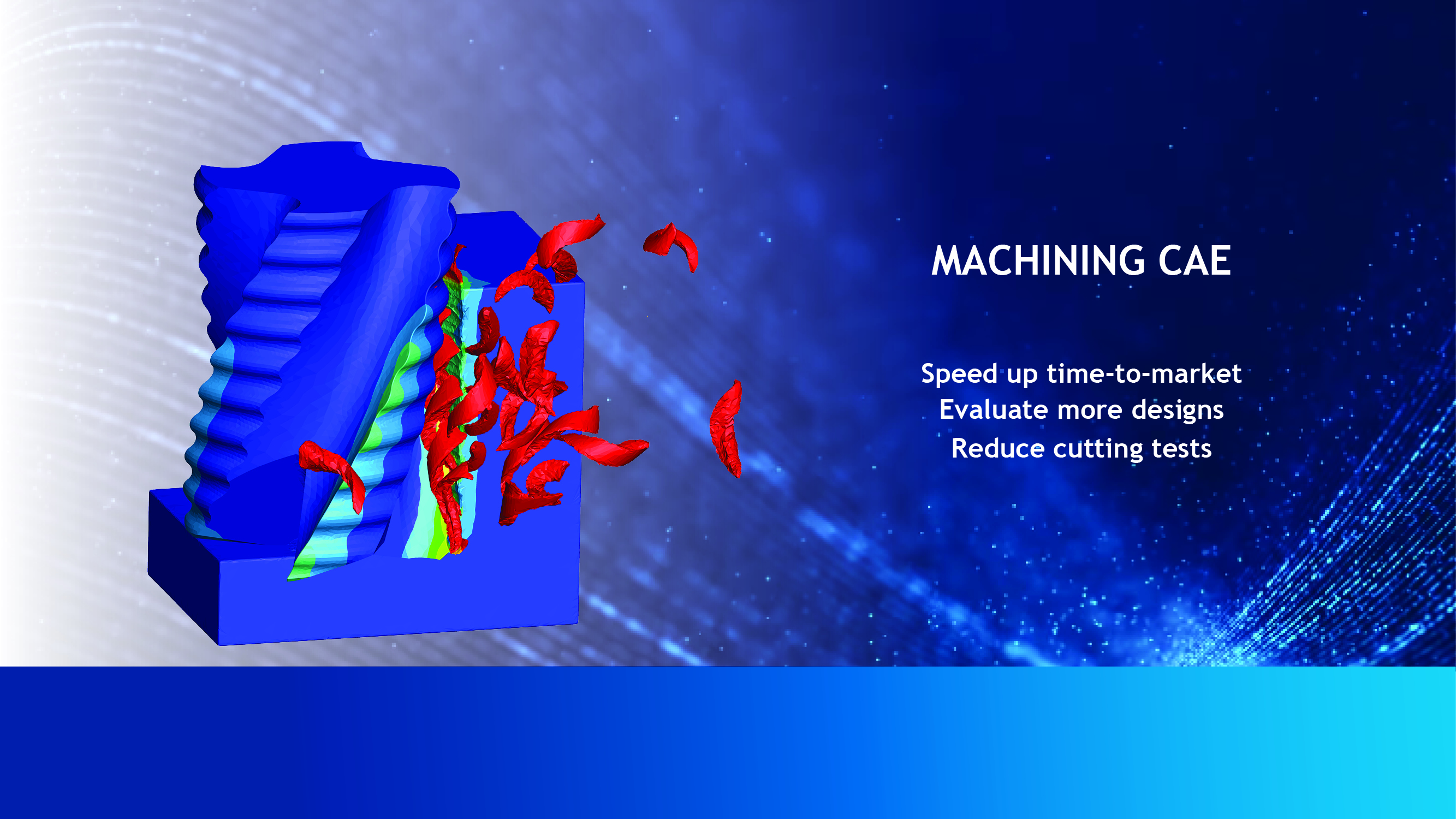

Introducing Machining AdvantEdge

A free flexible online course that's built to power the future of America’s manufacturers.

A free flexible online course that's built to power the future of America’s manufacturers.

If you have driven a car, ridden on a motorcycle, flown in a plane—or used nearly anything related to motion, chances are good the metal components were engineered using Third Wave Systems (TWS) technology. From the beginning, our vision has been for every high-value, motion-related component to be machined better using TWS technology. The unprecedented pace of change requires new thinking, better processes and stronger innovation for businesses to adapt and grow. Breakthroughs result from being bold, adapting nimbly, and relentlessly pursuing innovation. We call it bold innovation in motion and it’s what drives our vision.

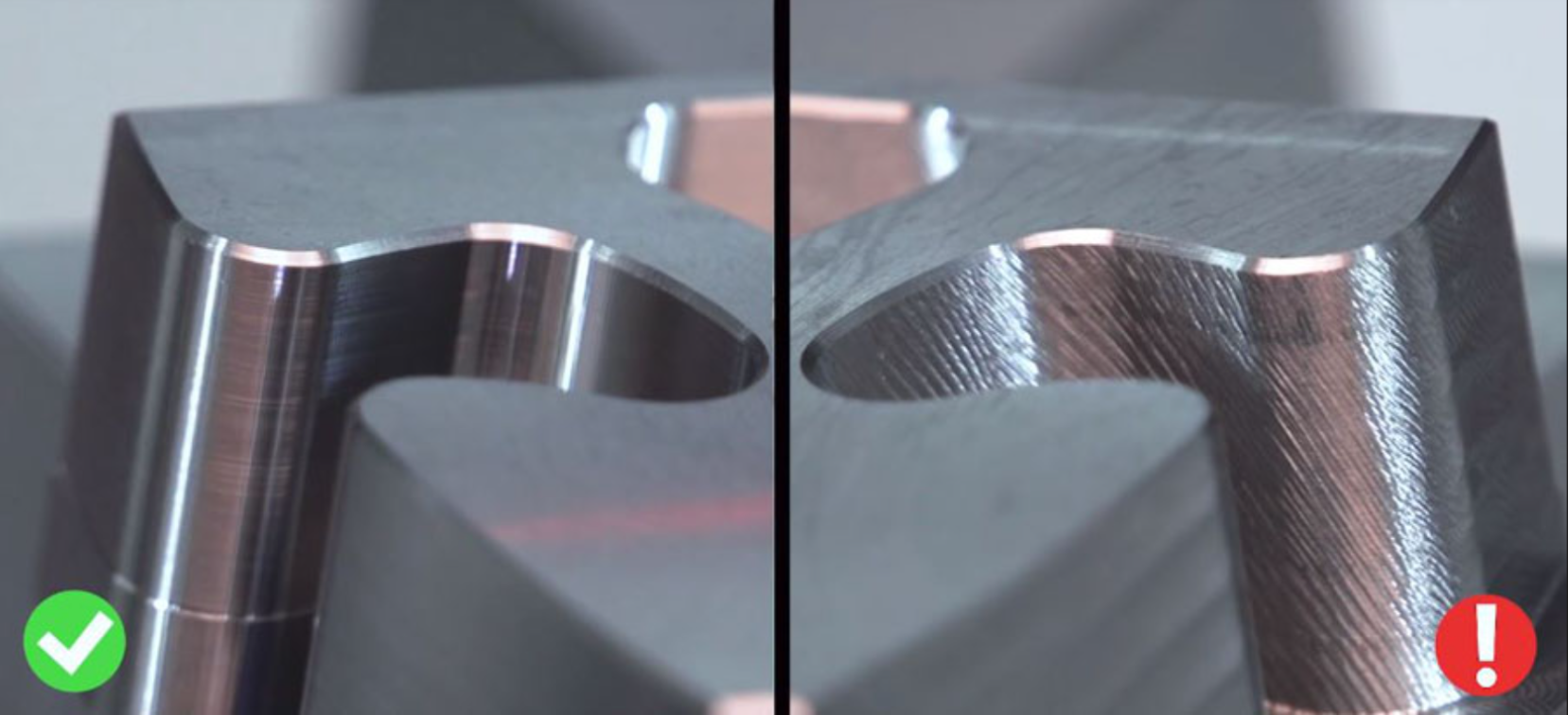

We are the premier material-specific, machining modeling solution turbocharging digital transformations within the largest automotive, aerospace, orthopedic and machine tooling brands in the world. Using high-performance cloud computing in concert with the brightest engineering minds in the industry, we help global leaders accelerate New Product Introduction (NPI), drive continuous improvement and deliver products faster. Benefits from leveraging Third Wave technology include:

We are privately-held, based in Minneapolis, Minnesota and have offices and distribution in North America, Europe, the Middle East and Asia.

Come join our movement.

Kerry Marusich – Founder/CEO

March 25-27, 2026

Machining Modeling Intensive at CCAT

East Hartford, CT

March 30-April 2, 2026

DMC

Orlando, FL

April 21-22, 2026

SMS Joint Seminar

Sandviken, Sweden

May 5-8, 2026

Grinding Hub

Stuttgart, Germany

May 20-21, 2026

Innovation Summit

Fort Worth, TX