Whether it is gash design for chip evacuation, or stress analysis for tool wear assessment or understanding the impact of a variable helix on axial force; the impact of process conditions on residual stress, comparing different toolpath strategies, or a myriad of other questions that you seek answers to, AdvantEdge and Production Module, can help get you those answers with fewer machining tests, improved quality, and accelerated time-to-market.

Third Wave Systems will also be presenting alongside prestigious market leaders at GrindTec 2022!

Presenter: Dr. Benedikt Thimm

Topic: Simulation Assisted Optimization of Metal Cutting Processes

16 March, 2022 | 03:30 – 04:00 PM

Visit us at GrindTec to discuss with our engineering team how we can help you in your quest for efficient machining solutions. We are excited to share our latest success stories following the new features and updates!

SUCCESS STORIES

NEW FEATURES

AdvantEdge

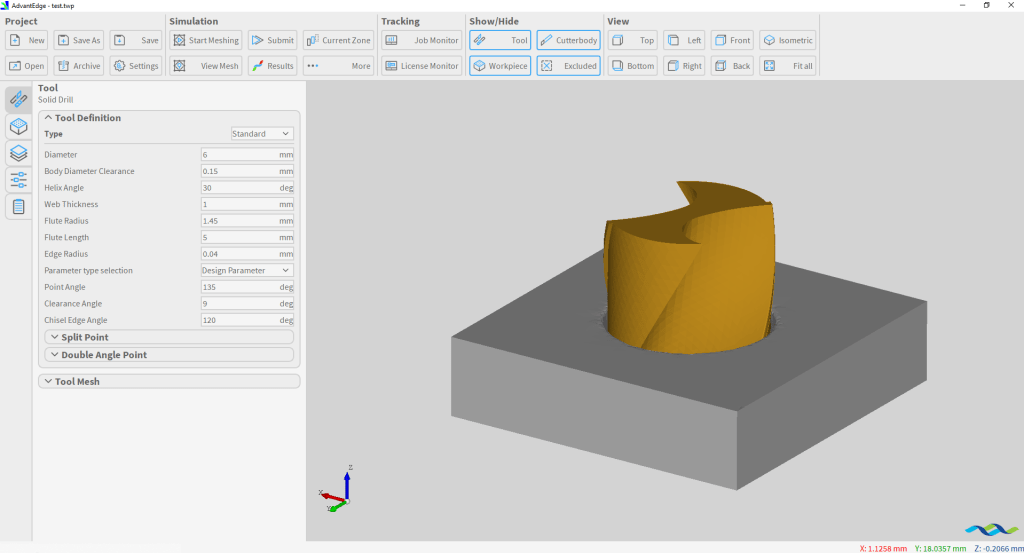

View details on the latest features, updates, and enhancements 1. Increased Ease of Use with the New AdvantEdge GUI We are excited to announce that the new AdvantEdge GUI is in the works and will be launched soon. AdvantEdge is known for its ease of use and the new GUI makes it even easier! 2. Tool and Holder Deflection Analysis – Reduce design iterations and engineer better processes In AdvantEdge, the users are able to model a tool holder and tool for analyzing deflection in turning and grooving processes. In addition, users can visualize displacement contours for the tool and the cutter body for all processes, including the custom kinematics processes. This analysis will help accelerate tool design cycles by providing a greater understanding of stress in the tool body and incurred displacement for a significantly larger parameter space than possible in cutting tests. This feature can also be used in process planning to ensure tooling systems don’t deflect excessively for improving part quality and even reducing tool breakage. 3. 40% Speedup in the last 6 months With the latest AdvantEdge, the users experience a computation speedup of 15% vis-à-vis AdvantEdge™ v7.7. This brings the total speedup to more than 40% in the last six months. The speed improvements target processes that require larger tools, as is the case with High-Efficiency Machining and processes using indexable tools modeled along with the tool holder. 4. User-Defined Kinematics to Model Complex Non-Standard Processes User-Defined Kinematics allows users to model complex and novel processes like spin tool turning, power skiving, thread whirling, bar peeling, and many, many more. Given the complex kinematics of processes, like power skiving, it is nearly impossible to experimentally measure even the forces experienced by the tool and the workpiece. The ability to model such processes using AdvantEdge becomes more critical to uncover new designs and process parameters. 5. Enable greater innovation in new materials with user-defined friction models Study and configure friction models for new age materials quickly and easily with AdvantEdge’s dramatically-expanded flexibility. Similar to UDYS functionality that enables constitutive equation modeling, AdvantEdge offers access to state variables from a simulation — in 2D as well as 3D, all to support greater innovation. To learn more about the advancements in AdvantEdge, click here!